1. Mechanics and Fatigue Fracture:

●Metal maʻamau mechanical hana ho'āʻo (-196 ℃--1000 ℃, tensile, compression, torsion, hopena, paakiki, elastic modulus);

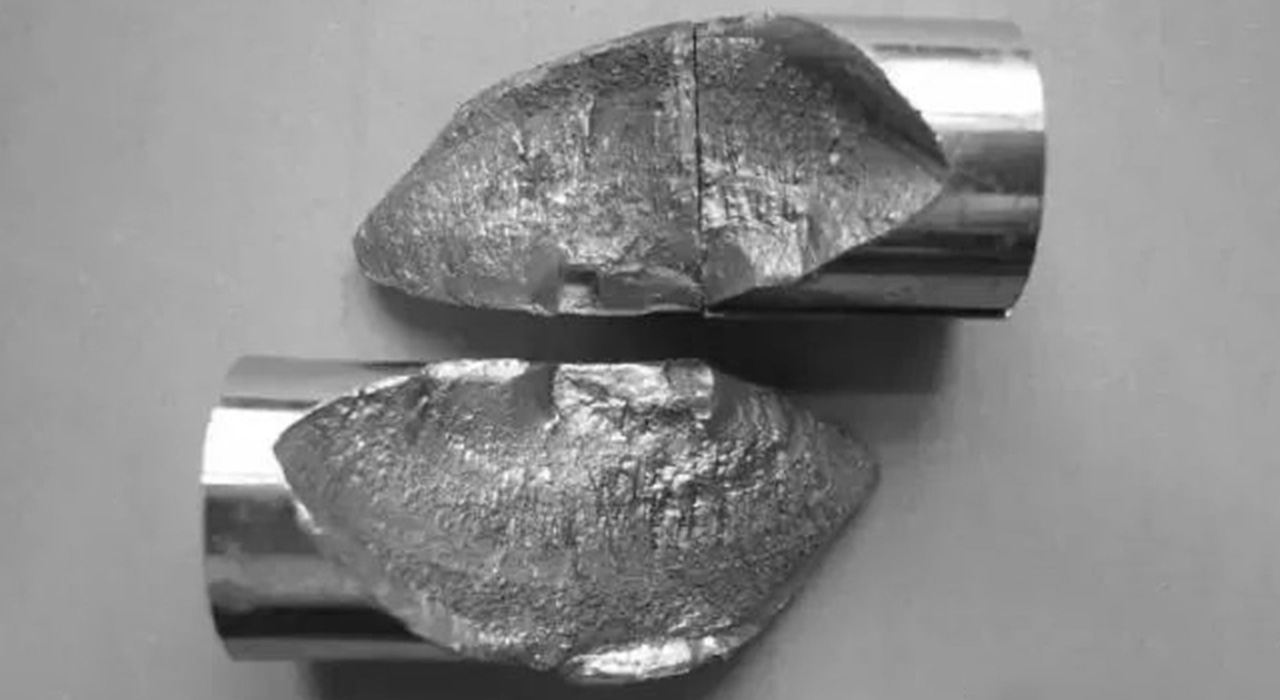

●Metal luhi a me ka haʻihaʻi hana ho'āʻo (-196 ℃--1000 ℃, axial kiʻekiʻe / haʻahaʻa pōʻai pōʻalo luhi, kahuli kulou luhi, māwae ulu ulu, haʻi paʻakikī, etc.);

●CTOD ho'āʻo o ka moku a me ka moana kila;ka wela haʻahaʻa haʻahaʻa, ka piko mānoanoa o ka pā mānoanoa

●Metal lōʻihi a me ke kiʻekiʻe wela creep hana ho'āʻo;

●Ka ho'āʻo hana o nā mea metala ʻole a me nā mea hoʻohui;

2. Kaʻa Kaʻaahi:

I ka pane ʻana i nā koi o ka ʻoihana kaʻa kaʻa no ke kaumaha māmā, ka ikaika kiʻekiʻe, ka hoʻokaʻawale ʻana i ka vibration a me ka hoʻohaʻahaʻa haʻalulu, ka palekana a me ka mālama ʻana i ke kaiapuni, ua lawe ʻia ka loiloi hilinaʻi o nā kaʻa kaʻa a me nā mea hana kaʻaahi, a hāʻawi ʻia ke alakaʻi alakaʻi a me ke kākoʻo ʻenehana. no ke koho ʻana i nā mea ʻāpana a me nā noi ʻenekinia.ʻO nā mea lawelawe nui:

● Ka loiloi hoʻokō piha o nā pāpaʻi alumini alumini ikaika kiʻekiʻe a me nā kiʻi no nā kaʻa kaʻa;

● Ka loiloi waiwai o nā mea nui e like me nā bogies, pahu pahu a me nā huila o nā kino kaʻa kaʻa;

● ʻO ka hoʻāʻo ʻana i ke kūpaʻa ʻino a me ka luhi o nā pale uwea kino kaʻa a me nā mea ʻē aʻe;

● Ho'āʻo ʻo Dynamic a static stiffness a corrosion resistance o ka track vibration damping fastener system;

● ʻO ka hoʻāʻo ʻana i ka lōʻihi o nā pad kaʻawale haʻalulu a me nā pad elastic o ka moena track;

● Ho'āʻo ikaika huki a luhi o nā mea hoʻopaʻa no ke kūkulu ʻana i ke ala;

● Ho'āʻo hoʻokō luhi o nā ʻāpana tunnel pale track.

● Ka ho'āʻo luhi o nā kaʻa kaʻaahi a me nā mea moe synthetic;

● Ka loiloi palekana o nā mea lawe ukana o nā alahaka;

3.Electric Power:

I ka ʻike ʻana i ka hopena o ka petrochemical a me ka lānahu kemika ma luna o nā mea hana, hiki ke hana ʻia nā noiʻi corrosion pūnaewele e hāʻawi i nā hopena maikaʻi no ka hana palekana o nā mea hana.ʻO nā mea lawelawe nui:

● Hoʻokolokolo ʻino (ana mānoanoa, kānana unahi, loiloi hemahema, ʻike mea, a pēlā aku);

● Kaʻina hana anti-corrosion a me ka nānā ʻana i nā manaʻo hoʻoponopono;

● Ka nānā 'ana i ka hemahema a me ka hō'ike 'ana i ke kuleana ulia pōpilikia;

● Ka loiloi palekana a me ka loiloi ola o nā ʻāpana kaomi.

4. ʻEnekinia Moku a me Moana:

Ma ke ʻano he "Ship Material Verification Test Center" i ʻae ʻia e CCS, hiki iā ia ke hoʻokō i ka hoʻāʻo ʻana a me ka hōʻoia ʻana no ka hana ʻana i nā moku a me nā makani makani waho, ka ʻaila a me ka hoʻomohala kinoea, nā kahua hoʻoheheʻe waho a me nā mea hana ʻē aʻe.ʻO nā mea lawelawe nui:

● Ka loiloi waiwai moku a me ka hōʻoia ma luna o ka moku;

● Ka loiloi hana o nā mea moku kūikawā (ka lawe ʻaila hinu, moku CNG, moku LNG);

● Ana ka mānoanoa o ka pā moku a me ka loiloi hemahema;

● Ka nānā 'ana i ka ikaika (ka hua a me ka noho 'ole) a me ka loiloi luhi o nā 'āpana o ka hull;

● ʻIke ulia pōpilikia o nā ʻāpana moku maʻamau (pūnaewele mana, ʻōnaehana hoʻopaʻa, ʻōnaehana paipu);

● Ka loiloi hilinaʻi o ka ʻenehana ʻenekinia waho;

● Ka loiloi hana uhi;

● Nānā, hōʻike hōʻike a me ka loiloi hopena o nā mea weliweli ma nā moku holo moana.

5. Ho'āʻo hoʻokō ʻino:

Hoʻohana nui ʻia ia e ʻike i ka hoʻāʻo ʻana o ka mea kemika a i ʻole ke kino (a i ʻole mechanical) kaʻina hana ʻino kemika i hoʻokumu ʻia e ka hui ʻana o nā mea metala a me nā mea ʻole me ke kaiapuni, i mea e hopu ai i nā ʻano o ka ʻōnaehana corrosion i hoʻokumu ʻia e ka mea. a me ke kaiapuni, a hoʻomaopopo i ka hana ʻino.E hoʻomalu pono i ke kaʻina hana corrosion.

● Ke kila kila intergranular corrosion, pitting corrosion a crevice corrosion

● Exfoliation corrosion a intergranular corrosion o ke alumini alumini

● ʻO ka hoʻāʻo ʻana i ka corrosion wikiwiki i loko e hoʻohālikelike i ke kaiapuni moana (ka hoʻolulu piha ʻana, inter-immersion, paʻakai paʻakai, galvanic corrosion, accelerated immersion corrosion, etc.);

● Electrochemical hana ho'āʻo o nā mea a me nā mea;

● Electrochemical hana ho'āʻo o ka mohai anode, auxiliary anode a kuhikuhi electrode;

● Sulfide stress corrosion a corrosion luhi;

● Ka loiloi hana a me ka ʻenehana hoʻāʻo ʻana o nā metala a me nā mea hoʻohui;

● Ka loiloi hana ʻino ma lalo o ke kai hohonu i hoʻohālikelike ʻia;

● ho'āʻo microbiological corrosion detection;

● Ka noiʻi e pili ana i ka ulu ʻana o ka māwae i loko o ke kaiapuni electrochemical;

● Kiʻekiʻe, waena a me haʻahaʻa māmā holo dynamic rotor scour simulation ho'āʻo

● ʻO ka hoʻāʻo ʻana i ka hoʻāʻo ʻana i ka hoʻāʻo ʻana i ka hoʻāʻo ʻana i ka hoʻāʻo ʻana i ka hoʻāʻo ʻana

● ʻO ka hoʻāʻo ʻana o ka hoʻāʻo ʻana i ka hoʻāʻo ʻana i ka hoʻāʻo ʻana o ke kai

● Ho'āʻo wikiwiki ʻia ka wai kai + ka ʻike lewa

6. Aerospace:

ʻO ka hoʻohui ʻana i ka hoʻohana ʻana i nā alumini alumini ikaika kiʻekiʻe, nā titanium alloys, a me nā mea i hoʻohui ʻia i nā mea nui e like me nā ʻenekini aero, nā ʻāpana alumini alumini a me nā ʻāpana, nā ʻāpana mokulele, nā mea hoʻolele mokulele, nā mea hoʻokele, nā propellers, etc. loiloi hana a me ka palekana Evaluate.ʻO nā mea lawelawe nui:

● ho'āʻo hana kino a me ke kemika;

● Ho'āʻo hoʻokō kino a me ke kemika ma lalo o ke kaiapuni lawelawe kūikawā (ultra-low temperature, ultra-high temperature, high-speed loading, etc.);

● Ka ho'āʻo luhi a me ka lōʻihi;

● Ka nānā 'ana a me ka loiloi ola.

7. ʻEnekinia Kaʻa:

Hiki ke hoʻokō i ka nānā ʻana i ka hilinaʻi a me ka nānā ʻana i ka maikaʻi o ka metala automotive, nā mea non-metal a me kā lākou mau ʻāpana.

ʻO nā mea lawelawe nui:

●Metal mea ho'āʻo (ka ho'āʻo hāʻule, mechanical waiwai ho'āʻo, microscopic kālailai, metallographic kālailai, ka uhi ana kālailai, corrosion hoao, haʻihaʻi kālailai, welding inspection, non-destructive hoao, etc.);

● ho'āʻo corrosion a me ka luhi.